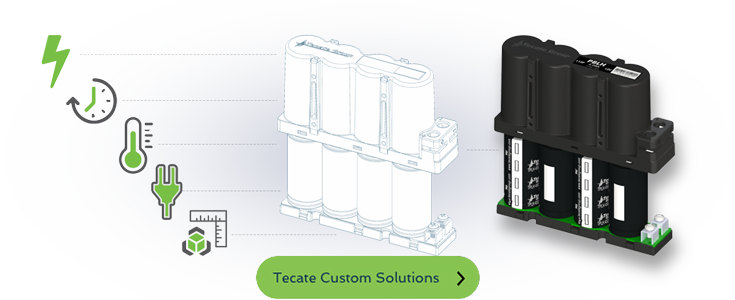

Tecate Ultracapacitors

Tecate offers a wide range of standard and custom ultracapacitor modules and cells for sale in various voltage and capacitance levels.

View Ultrapacitor Products

Tecate Capacitors

Tecate carries a comprehensive inventory of industry-standard products in both through-hole and surface-mount configurations.

View Capacitor Products

Tecate Hybrid Capacitors

Tecate Group’s hybrid (lithium-ion/LIC) capacitors offer the increased voltage and energy density of batteries along with the rapid charge/discharge, environmental friendliness, longevity, and safety of ultracapacitors.

View Hybrid Capacitor Products

Search for Parts

Use the part finder below to locate the Tecate product that best meets your needs.